Quality is at Graff Kristensen A/S defined as; "the fulfillment and meeting of our customers’ expectations". To reach this goal, we have combined our quality control system "Go!Fact" with our organization. This means, that we at Graff Kristensen A/S have both a production manager and a quality manager. The objective of our quality manager is to be the ambassador of our plants, and always ensure that the plants welfare are in focus, even though our industry sometimes experience pressure both in "peaks" and cost terms. All Hibiscus at Graff Kristensen A/S are sorted in 5 quality categories;

- Grade B

- Grade 2+

- Grade 3+

- Grade 4+

- Exclusive!

Insuring everybody in the supply chain knows the different quality categories we use different wrapping, sleeves etc. for diffrent grades.

To maintain the internal quality of our HibisQs® we recommend both retailers and our consumers to place their HibisQs® in a bright and if possible sunny place. The sun is paramount for every Hibiscus to flower and stay in good quality.

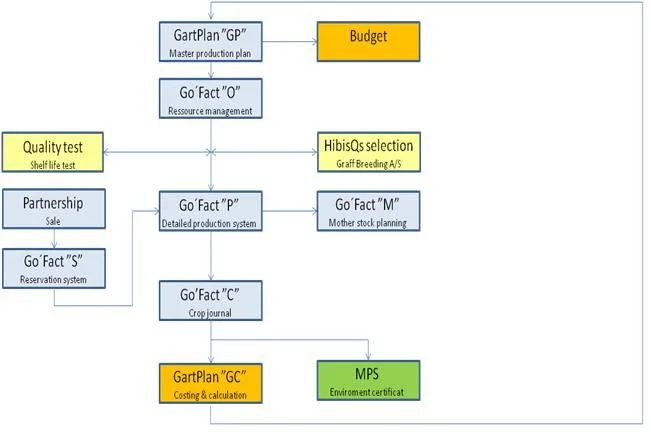

Quality and production controlling systems

To produce live plants of high quality, and long life requires professional competence and systems. Once we have the living plant growing, quality is affected by a wide ranges of factors. This necessitates a very detailed quality- and production system and an explicit and proficient monitoring program.

To meet these expectations, we have developed the comprehensive Go!Fact standard, which consists of a series of modules that ensures both quality and production can be managed and customized down to the smallest detail.

With this tool, we can indeed meet the thoughtful customers' expectations for quality, delivery, and predictability.